ROFIN - customer-tailored laser processes for medical device manufacturing

source:Rofin

keywords: laser processes medical device

Time:2016-12-05

ROFIN has been developing laser systems, primarily complete solutions, for the medical device industry for more than three decades, and offers a comprehensive range of laser technologies – starting with laser sources, through to customized solutions – all from a single source. The focus is always on top quality processing results, along with machine reliability and optimized uptime. Take ROFIN’s record setting stent cutter as an example. The 5th generation StarCut Tube system has been in constant operation at the customer site for more than 120.000 hours, with up-time greater than 95%.

Lasers supersede established processes

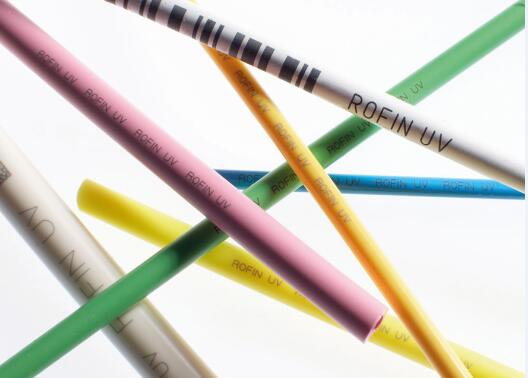

While some processes in medical device manufacturing are simply not possible without lasers – such as stent cutting - there’s still a multitude of applications which could heavily benefit from laser material processing. As a recent example shows, when a ROFIN laser marking solution replaced pad printing in bulk production of medical consumables. Despite the higher initial investment the total cost of ownership is lower across the life of the process. Significantly improved manufacturing quality with less production waste, and considerably reduced personnel and maintenance costs outweigh the higher investment in a short time. Not to mention the dramatically improved flexibility the laser offers.

Fig. 1: The most compact laser tube cutting system now with fiber or femto laser

High-tech for heart valve replacements

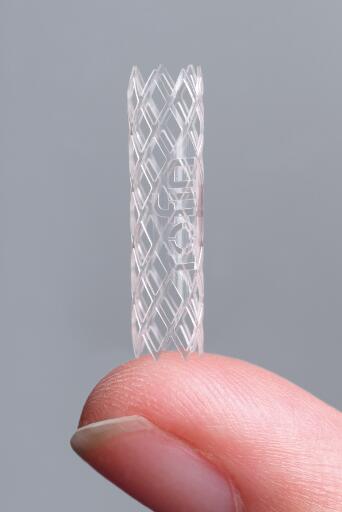

More and more elderly patients receive their heart valve replacement via trans-aortic valve implementation (TAVI) of framed Xenografts. Tissue from cattle or pigs is sewn into a self-expanding, laser cut metal frame. Global leaders in heart valve manufacturing rely on StatCut Tube systems from ROFIN.

Fig. 2: Cutting of bioresorbable scaffolds in highest quality

Integrated solutions to meet UDI requirements

Since the end of 2014, certain medical products for the American market have to comply with the UDI "Unique Device Identification" requirements. These labelling requirements will be extended to virtually all products, and also to the European market. In cooperation with medical device manufacturers, ROFIN has been developing integrated, UDI compliant solutions for the entire laser process chain from production to packaging.

Fig. 3: Laser marking for biocompatible, rich in constrast and flexible marking

Process know-how, laser technology and mechanical engineering from one source

ROFIN always considers the laser process to be part of a comprehensive solution. Frequently, this requires more than an optimized laser system, but also customer-tailored work holding and efficient solutions for part loading and removal. ROFIN is one of the few worldwide laser manufacturers which is able to cover all relevant competence areas. Additionally ROFIN’s application engineers will help with the evaluation and development of applications upon request. This is how excellent laser systems lead to best-of-breed solutions for medical device manufacturing, supported by world-wide, local service presence.

Fig. 4: Laser cutting, laser welding, laser marking – ROFIN one supplier for all solutions

MOST READ

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

PRODUCTS

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>